Modular design

In addition to different power categories, there are two handle versions that can be equipped with different operating elements and torch body versions.

That’s possible because the new TIG welding torches can be individually adjusted to suit your personal preferences or the application at hand.

Do you find a large or small handle easier to hold? Or would you prefer to control your power source from the torch? Maybe you want to improve component accessibility through the wide range of gas nozzles and torch bodies? Regardless of your needs, our TIG welding torches offer you maximum flexibility.

Fronius welding torches represent the perfect blend of technology and ergonomics. The ergonomic handle with non-slip components sits comfortably and securely in your hand, allowing the torch to be guided with ease. Various operating concepts take care of the most varied welding requirements. Depending on the application, welders can choose between a standard or a small handle hosepack.

Simple conversion* from the user interface, only one screw needs to be unscrewed.

*) Option only applies to standard handle

The Small Handle is a convenient smaller alternative to the standard version. It is particularly well-suited to difficult-to-access weld locations in less power-intensive applications and is the more ergonomic choice for smaller hands. Despite its smaller size, it still offers a variety of different control options too.

Flexible welding made easy: the modular construction of the new TIG Multilock welding torch allows the torch to be customized to suit practically any customer requirement. Multiple torch cap sizes as well as a rotatable torch body available in several lengths help overcome challenging accessibility situations and make handling the torch a breeze.

Different torch body lengths ensure maximum flexibility while welding.

Depending on the application and component condition, torch caps of various sizes can be used.

The flexible torch bodies can be bent into the desired position for difficult to access welding points.*

More than 80 gas nozzles available.

MULTILOCK

/ Quick and easy torch body changes

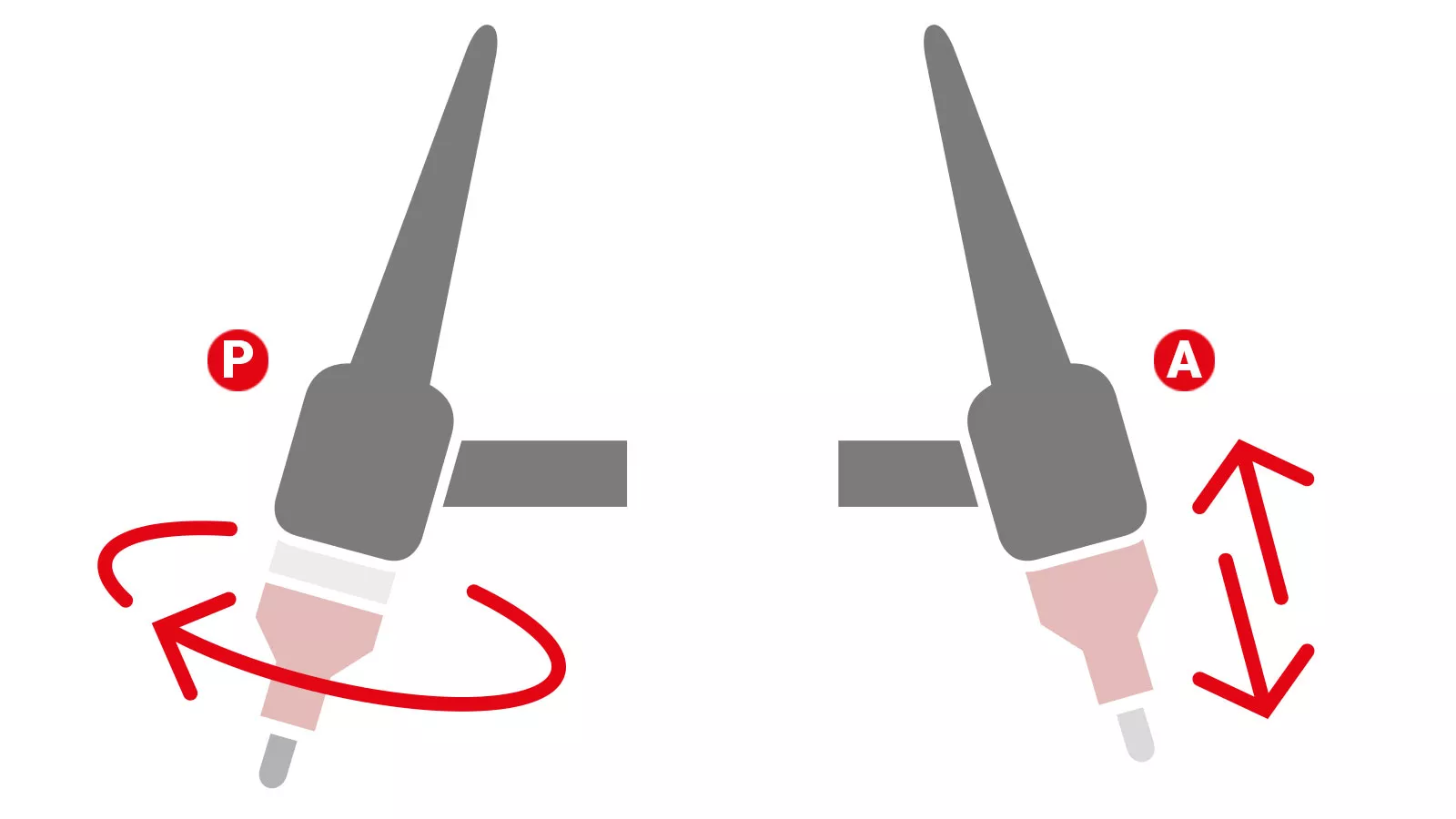

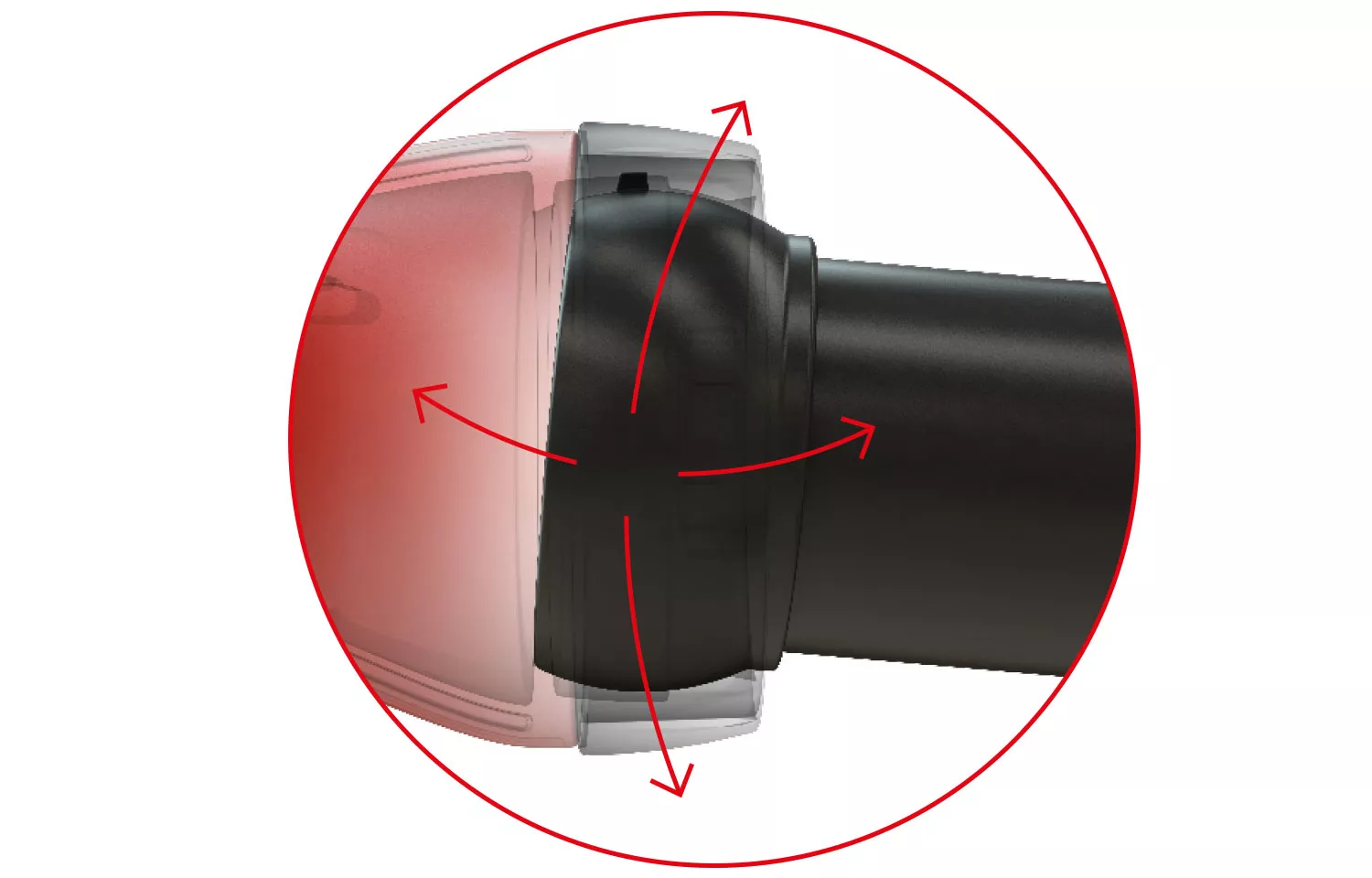

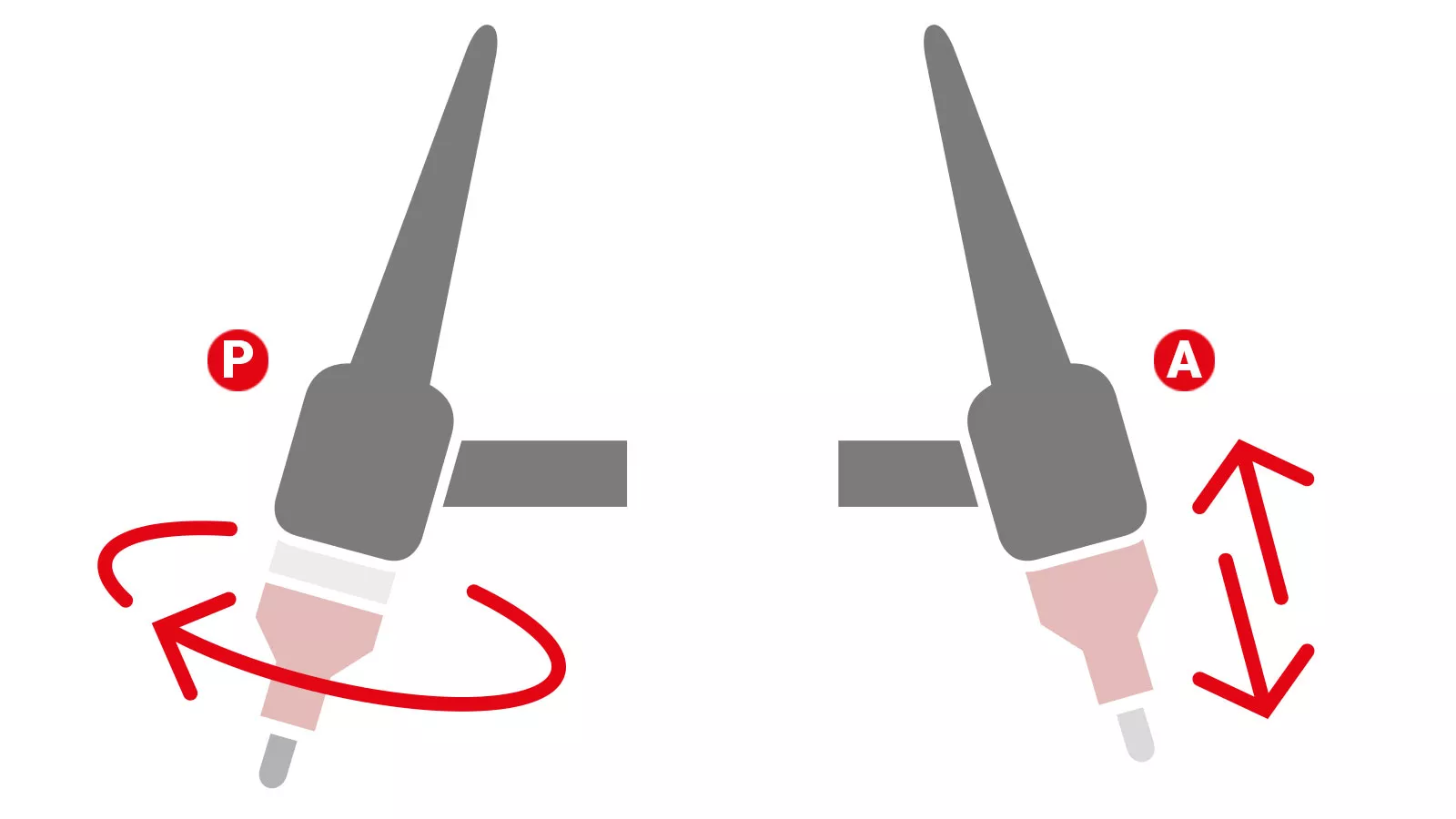

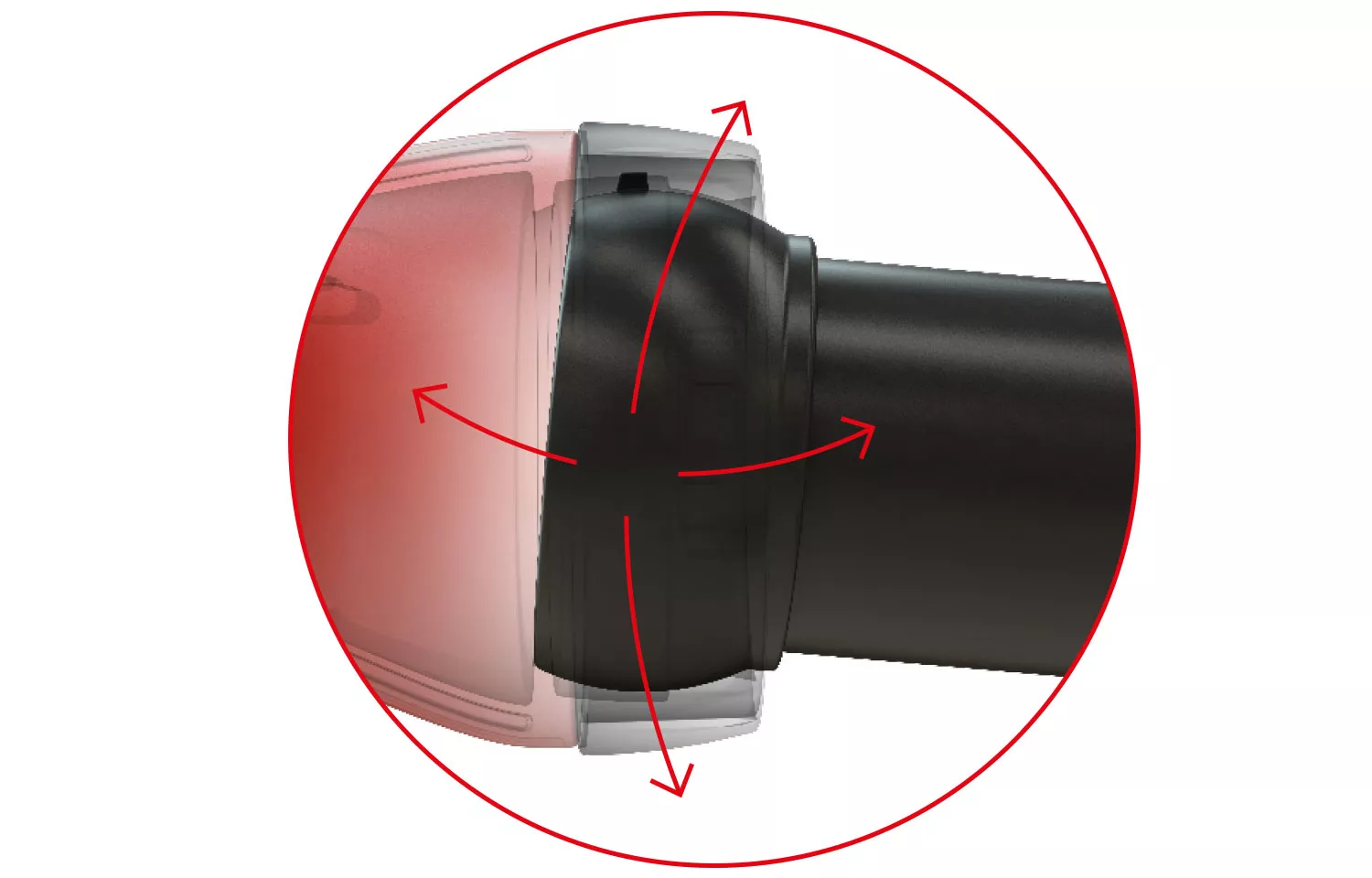

/ Torch body can be turned through 360°

/ Over 40 different torch bodies

Illumination of the welding area before and after welding

/ Tool-free mounting

/ Shielding gas directly at the power connection

/ External water connections

/ Water-cooled bayonet connection for high performance

MULTILOCK

/ Quick and easy torch body changes

/ Torch body can be turned through 360°

/ Over 40 different torch bodies

Illumination of the welding area before and after welding

/ Tool-free mounting

/ Shielding gas directly at the power connection

/ External water connections

/ Water-cooled bayonet connection for high performance

The innovative advantage of Fronius TIG DynamicWire, when compared to a conventional continuous wire feed in cold wire systems, lies in its automatic self-regulation.

The power source actively adjusts the wire speed to the welding behavior, torch position, and current conditions, even compensating automatically for component tolerances of up to 30%.

To TIG DynamicWire

Standard hosepacks can be extended by 10 meters with this option. The connection point is packed in a compact and robust pouch to prevent contamination and snagging.

In order to prevent improper use of the Multilock System, hosepacks can be optionally equipped with a release lock.

This option offers advantages when used with a foot controller or the touch HF ignition (the high-frequency ignition starts after the workpiece is touched by the electrode).

Hosepacks can be converted to pushbutton operation for the digital device generation. Functions include start and end of welding as well as intermediate lowering.

With this system, you can change the tungsten electrode quickly and effortlessly.

The touch of a button is all it takes to release and re-clamp the electrode—and all in just a few seconds, ensuring outstanding efficiency and uninterrupted work with no unnecessary downtime.

It is also possible to retrofit the TFC system to your existing TIG welding torches.